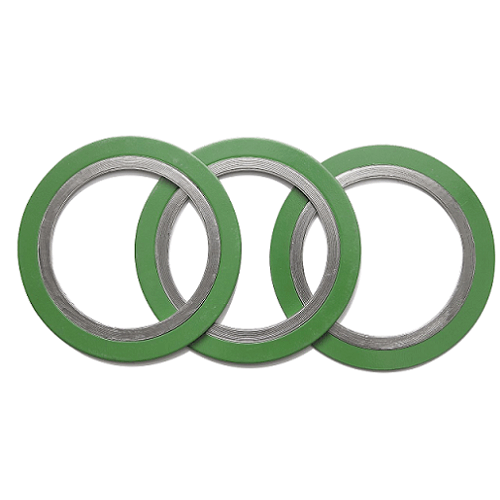

Spiral Wound Gasket

A Spiral Wound Gasket is the most common metallic gasket used in industrial plants and a selected and installed spiral wound gasket can withstand high temperatures and pressures.

Send Inquiry

Product Description

What is A Spiral Wound Gasket?

SN500 Spiral wound gaskets provide excellent sealing efficiency and continuous compressibility. The process of highly accurate winding density control provides a spiral wound gasket made to satisfy your specified seating stress and guarantees continuous sealing of your most critical fluids. Kaxite™ Spiral Wound Gaskets are durable and easily installed and removed. Kaxite™ gaskets seal pressures to flange ratings, according to ASME B16.20. The Kaxite™ series of gaskets provide many different situations by incorporating various metals and filler materials. They are perfect for hydrocarbon processing and refining, petrochemical processing, chemical processing, power generation, pulp and paper, and oil and petrol industries

The Spiral Wound Gasket Construction Structures

The spiral wound gasket is made by specially formed V Shape metal strip and a soft gasket filler material such as graphite or PTFE Tape. The Gasket can include a outer centering ring and inner ring or both. The outer ring mainly centers the gasket between flanges, while the inner ring provides strength and also lowers internal turbulence and helps to protect the sealing elements.In a Word, the spiral wound gasket consists of 3 main structure as below

Winding Ring: made of stainless steel such as ss304, ss316L, ss321, Monel 400, and mixed with a filler such as Graphite or PTFE

Inner Ring: Material used usually same as the Winding Ring

Guide or Outer Centering Ring: Mostly Carbon steel painted, also stainless steel like ss304, ss316

And the gasket thickness usually is: 4.5mm, 3.2mm and 6.4mm, custom thickness can be accepted

Types of Spiral Wound Gasket

So according to the spiral wound gasket Construction Structure, the gasket manufactured and supplied by us Ningbo Kaxite™ can have 4 main types as Below

2. SN 500-RIR Type: Spiral Wound Gasket with Inner Ring

3. SN 500-CG Type: Spiral Wound Gasket with Outer Centering Ring

4. SN 500-CGI Type: Spiral Wound Gasket with Inner and Outer Ring

Basic Type Spiral Wound Gasket - SN 500-R

Basic type Spiral wound gasket construction type just with a winding ring, with no inner or outer centering ring. Its inner and outer diameters are strengthened with some piles of metal strips without filler to offer great stability and compression characteristics. It is ideal for tongue and groove, male and female or grooved to flat face flange assemblies.

Spiral Wound Gasket with Inner Ring SN 500-RIR

Spiral wound gasket solid inner metal ring behaves as a compression stopper to avoid accumulation of solids, decrease turbulent flow of operation fluids and reduce erosion. And avoid damages of gasket between flange bore and the inside diameter as the annular space of flange is filled up by solid inner metal ring. Suitable for male and female pipe flanges.

Spiral Wound Gasket with Outer Ring SN 500-CG

By means of suitable dimension of the centering ring, the sealing element is accurately centered on the flange face by the bolts. The outer ring of spiral wound gasket can Protect the spiral wound sealing element. Suitable for male and female pipe flanges.

Spiral Wound Gasket with Inner and Outer Ring SN 500-CGI

This type of spiral wound gasket is with inner and outer centering ring, the inner and centering ring will give an additional compression limiting stopper for gasket inner and outer side. It will prevent the corrosion on flange faces at annular space. Suitable for used with flat face and raised face flanges and specified for high pressure temperature service class 900 and above or other situations

Standard Specification

Spiral wound Gaskets are manufactured in accordance with all relevant gasket standards to suit flange designations: ASME B 16.20, MSS SP-44, API 605, DIN 2632-2638 DIN EN1514-2, JIS B2404, BS EN1514-2 , etc. Or products can be customized according to the users' requirements (no-standard spiral wound gasket). Please provide the specific drawings if the gasket is no-standard.Main Applications of Spiral wound gaskets

Spiral wound gaskets can be used in applications where high temperature and high pressure, also in low temperature applications like in cryogenic facilities, chemical plants, and research laboratories. As the spiral wound gasket can be adjusted automatically, it is especially suitable for the occasions where the load is uneven, the joint force is easy to relax, the temperature and pressure change periodically, and there is impact or vibration. It is a static sealing element for flange joints of valves, pumps, heat exchangers, towers, manholes and handholes. It is widely used in petrochemical, mechanical, electric power, metallurgy, shipbuilding, medicine, atomic energy and aerospace departmentsBelow Reasons Are Why Spiral Wound Gasket is so Popular and Its Advantages

• Combinations of metal strip and filler are selected to suit the specific fluid media and operating conditions.• Make gaskets suitable for high pipeline pressure on flat or raised flange faces.

• Gasket are made in a wide variety of sizes and shapes.

• Temperatures from cryogenic up to 1000 °C

• High and low temperature resistance

• Quick to install and remove

Materials For Spiral Wound Gasket

Winding Material available in: 304 SS, 316L SS, 321 SS, 347 SS, Inconel® 600, Incoloy® 800/825, Inconel® X-750, Monel®400 Winding for corrosive environments - Alloy 20, Hasteloy® C-276, Monel® 400Winding Fillers available: Non-Asbestos tape, Flexible Graphite tape, Flexicarb®, Mica tape, Ceramic, PTFE tape, Non-sintered PTFE High temperature mica tape filler now available

Inner Rings available in: 304 SS, 316L SS, 321 SS, 347 SS, Inconel® 600, Incoloy® 800/825, Inconel® X-750, Monel® 400

Outer Centering Rings available in: Painted Carbon Steel, 304 SS, 316L SS, 321 SS, 347 SS, Inconel 600, Incoloy 800/825, Inconel X-750, Monel 400

Spiral Wound Gaskets Stainless Steel Color Code

| Metal Material | Min temp | Max Temp. | Guide ring color | Ring color |

| SS 304 | -320 °F |

1400°F |

YELLOW |

|

| SS 316L | -150 °F | 1400°F | GREEN |

|

|

SS 317L |

-150 °F |

1400°F |

MAROON |

|

| SS 321 | -320 °F |

1400°F |

TURQUIOSE |

|

|

SS 347 |

-320 °F |

1700°F |

BLUE |

|

|

A-20 |

-300 °F |

1400°F |

BLACK |

|

|

Carbon steel |

-40 °F |

1000°F | SILVER |

|

|

HAST B2 |

-300 °F |

2000°F | BROWN |

|

|

HAST C 276 |

-300 °F |

2000°F | BEIGE |

|

|

INCOLOY 800 |

-150 °F |

1600°F | WHITE |

|

|

INCOLOY 825 |

-150 °F |

1600°F | WHITE |

|

|

INCONEL 600 |

-150 °F |

2000°F | GOLD |

|

|

INX |

-150 °F |

2000°F | No Color |

|

|

MON 400 |

-200 °F |

1500°F | ORANGE |

|

|

NIKEL 200 |

-320 °F |

1400°F | RED |

|

|

Titanium |

-320 °F |

2000°F | PURPLE |

|

Spiral Wound Gasket Filler Color Code

| Gasket filler | Abbr. | Min temp. | Max Temp. | Strip color code | Strip color code |

| Ceramic | CER | -350 °F | 2000 °F | LIGHT GREEN |

|

| Flexible Graphite | FG | -350 °F | 950 °F | GRAY |

|

| PTFE | PTFE | -400 °F | 500 °F | WHITE |

|

| Mica graphite | MICA-GRA | -350 °F | 1400 °F | PINK |

|

How to Order Spiral Wound Gasket

To Order Spiral Wound Gaskets, you need offer inforemation as Below• Gasket Type

• Size

• Pressure Class rating

• Winding Material

• Filler Material for gasket

• Outer Ring Material (if applicable)

• Inner Ring Material (if applicable)

• Are MTR's required?

Hot Tags: Spiral Wound Gasket, China, Manufacturers, Suppliers, Factory, Wholesale

Related Category

Sanitary Tri-clamp Gaskets

Copper Metal Gaskets

Kammprofile Gaskets

Silver Gasket

Metal Jacketed Gaskets

PTFE Gasket Washer

Non-asbestos Fiber Gasket

Flexible Graphite Gasket

Ring Type Joint Gasket

Spiral Wound Gaskets

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.