Flexible Graphite Packing

Send Inquiry

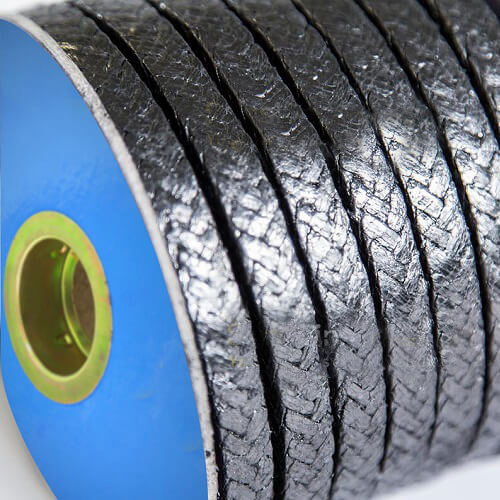

Flexible Graphite Packings - Style 3000

Style 3000 Flexible Graphite Packing is manufactured from high purity flexible graphite which is expanded and shaped into a graphite yarn and then braided without wire reinforcement. The Flexible Graphite Packing keeps all the original benefits associated with flexible graphite: great heat resistance, chemical inertness, low friction, self lubrication.The fantastic attributes for this Flexible Graphite Packing make it ideal for different service purposes within a plant. Flexible Graphite Packing could be used in valves, pumps, expansion joints, mixers and agitators in the aggressive environments of hydrocarbon processing, pulp and paper, power generation, metal-working and other industries where successful sealing is necessary.

Besides the Compression Flexible graphite packing, the graphite packing can be reinforced by added materials such as ss304 wire, ss316 wire, inconel wire, carbon fibers, fiberglass, cotton fiber and so on. The density of the packing is about 1.2g/cm3. And sizes from 3mm to 60mm.

Other Types of Flexible Graphite Packing

Style 3002- Flexible Graphite Packing with Glass FiberStyle 3004- Flexible Graphite Packing with Cotton Fiber

Style 3006- Flexible Graphite Packing with Metal Wire Reinforced

Style 3008- Flexible Graphite Packing with Inconel Wire

Style 3010- Flexible Graphite Packing with PTFE Impregnated

Style 3235- Inconel Wire Jacket Graphite Valve Packing

Features and Advantages of Flexible Graphite Packing

Flexible Graphite Packing offers economical alternatives to asbestos fibers packing, lessen maintenance time and charge. It is easy to setup and work as a good seal in used or oversize stuffing boxes. The braided type and construction of the flexible graphite packing optimize reliability and also steadiness in high temperature ranges, provide fantastic chemical substance resistance, and dissipates heat speedily. Apparatus goes much cooler as well as requires a lot less flush water. The braided gland packing can include a not aggressive corrosion inhibitor like Zinc Powder. No more end ring material is required with regard to valve installations.What is Flexible Graphite Packing Used For:

Style 3000 Flexible Graphite Packing is definitely precise to seal all sort of industrial valves, making use of all liquids and gases, with the exception of the strong oxidizers. Perfect for by using in rotary pumps and valves in power stations as well as boiler houses, in the petrochemical industry and many other industrial spots. Stay away from combustion gas and also heat over 450°C. The valve's pressure has to be under 100 bar if the packing is not helped by high tension wiper.Service Range:

| Temperature |

|

PressureLimit |

|

| Min Temp | - 240 °C | Static | 300 bar |

| Max Temp |

450 °C |

Rotating | 30 bar |

|

|

650 °C in steam |

Reciprocating |

100 bar |

| Shaft Speed | 20m/s | Ph | 0 - 14 |

The best way to set up Flexible Graphite Packing correctly as well as Cut.

The necessity of using compression braided gland packing for pumps correctly simply cannot be overemphasized. A number of packing failure problmes are caused by inappropriate installing of the packing. The following tips are actually developed to make sure the most effective setting up packing on pumping systems:Eliminate all the outdated packing out of the stuffing box: Clean up box and also shaft totally and also examine your shaft or sleeve. Remove and take the place of shaft or sleeve when a lot wear.

Use the appropriate cross section of packing or die-forming rings: To determine the proper packing dimension, measure the diameter of your shaft (inside the filling box area when possible) as well as after that measure the diameter of the stuffing box (to give the outer diameter of the ring). Subtract the inner diameter size coming from the outer diameter measurements and divide by two. The result will be the needed measurements.

When using coil as well as spiral packing, often cutting the packing into different rings: Do not ever wind a roll of packing into a stuffing box. Braided Gland Packing Rings can be cut into butt shape (rectangular), bias or diagonal joints, based on the construction. Our recommendation is that flexible graphite packing be cut only by butt (sq) technique. The easiest method to cut braided gland packing rings is usually to cut the packing on a mandrel with the same diameter as the shaft on the filling box area. When there is not shaft abrasion, rings can be cut on your shaft away from the stuffing box. Contain the packing tightly on the mandrel, nevertheless tend not to stretch out extremely. Cut the ring as well as insert it into your stuffing box, making certain it will fit the packing place properly. Every single added ring can be cut on the same manner, or the very first ring might be used as a master in which the balance of the rings are cut. It is actually needed the fact that rings be cut towards the right measurement. In any other case, service life is diminished. This is when die-cut rings are actually of wonderful benefit, as they provide the precise ring measurements for your inner diameter of the shaft as well as the outer diameter of the stuffing box. There is absolutely no waste materials on account of falsely cut rings.

Setup one ring at one time: Be sure that it can be thoroughly clean, as well as has not collected any dirt in delivering. If perhaps desired, lubricate the shaft within the stuffing box. Seat rings firmly (except PTFE filament or Graphite yarn packing, which ought to be snugged up very carefully, next tightened stage by stage after the pump is on steady flow). Joints of subsequent rings must be staggered and also held at the very least 90 degrees a part. Every unique ring ought to be firmly seated with a tamping device. If enough rings have already been individually sitting so your nose of the gland will get to them, unique tamping really should be compounded by the gland.

Right after the very last ring is certainly installed, take up mounting bolts finger snug or slightly snugged upward. Tend not to jam the packing into area by excessive gland launching. Start off pump, as well as take up bolts until such time as leakage is lessened to a tolerable minimum. Make sure gland bolts are taken up equally. Quitting LEAKAGE ENTIRELY After All This WILL CAUSE THE PACKING TO BURN UP.

Enable packing to leak freely once establishing a newly packed pump:Abnormal leakage over the 1st hours of procedure will result in a better packing job during a longer amount of time. Take up gradually on the gland as the packing seats, until finally leakage is lowered to a endurable degree. Do not ever attempt to avoid leakage entirely, except if we indicate it is safe and sound to do so.