Home > Products > Industrial Sealing Gaskets > Kammprofile Gaskets > Kammprofile Grooved Gasket with Integral Outer Ring

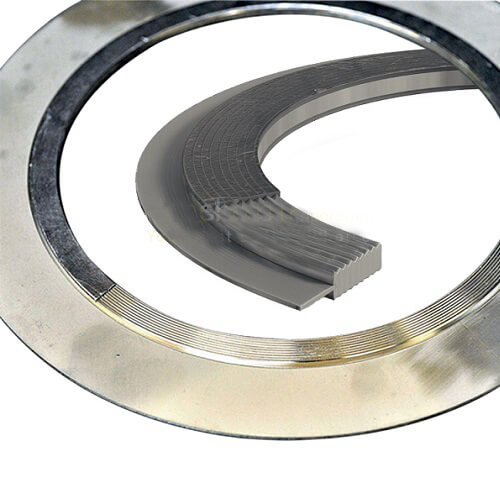

Kammprofile Grooved Gasket with Integral Outer Ring

Kammprofile grooved gasket with integral outer ring, the outer ring is fixed and not floating type. It can be used for many industries and be made from various stainless steel materials.

Send Inquiry

Product Description

Style Kam 322 - Grooved Gasket with Fixed Outer Ring

Kammprofile Grooved Gasket with Integral Outer Ring delivers excellent durability in tough programs. Kammprofile Grooved Gasket with Integral Outer Ring we create cater to normal ASME flanges in addition to non-standard flanges such as lighter in weight flanges, valves, pumping systems, flanges, heating exchangers and vessels. Kammprofile Gaskets are also a fantastic choice for aged, worn out heat exchangers originally suitable for jacketed gaskets. The gasket manages stresses from whole vacuum to your utmost rating of the flange as well as withstands temperature conditions from cryogenics to 1100°C, based on sealing material as well as serrated steel core.The height and user profile of your groove serrated metal is especially structure to help densification of your experiencing fabric and also create a very leakless seal with very low gasket tensions.

Kammprofile Grooved Gasket VS Spiral Wound gaskets

As opposed to a spiral wound gasket, all of the compressive pressure is applied for the kammprofile graphite facing, as a result causing a very firm sealing effect. Kammprofile gaskets compress observably less than spiral wound gaskets. Ever since the kammprofile is certainly reliable steel, compared to alternating layers of steel and also filler of spiral wound gaskets, it is rather resilient and easy to handle. And for price, kammprofile gaskets tend to be more costly than spiral wound gasket. Having said that, their own greater upfront fees might be paid by preventing pricy, unscheduled outages as well as loss in creation. Spiral wound gaskets may have a little benefit in case the mating flanges are way too near and also if the gasket is expected to be subject to mechanised damage or abuse during set up, because the graphite facing is much more more prone to mechanised destruction. Moreover, in some situations, spiral wound gaskets could possibly be much more resistant to oxidation, considering that the windings keep your graphite in place as well as guard it. On the other hand, kammprofile gaskets tend to be more tolerant to sealing area problems.Properties

Could be manufactured to suit standard flange purposes and vessels.Ideal for used in high pressure and high temperatures applications.

Is often manufactured to get used with small flanges

Low sealing pressure required for setting up.

Can be remodeled and recycled.

Ideal for a range of chemicals.

Hot Tags: Kammprofile Grooved Gasket with Integral Outer Ring, China, Manufacturers, Suppliers, Factory, Wholesale

Related Category

Sanitary Tri-clamp Gaskets

Copper Metal Gaskets

Kammprofile Gaskets

Silver Gasket

Metal Jacketed Gaskets

PTFE Gasket Washer

Non-asbestos Fiber Gasket

Flexible Graphite Gasket

Ring Type Joint Gasket

Spiral Wound Gaskets

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.